Sustainability, the great challenge for the packaging sector

Most of the waste that citizens generate in industrialized countries is made of packages and food containers. Consumption of industrial products of all types has multiplied in the last decades, inevitably the same as the materials used to package them. This is a sector that has been developed based on the ‘product, use, discard’ model. The same model has filled the earth with landfill sites, as well as the oceans and seas with plastic.

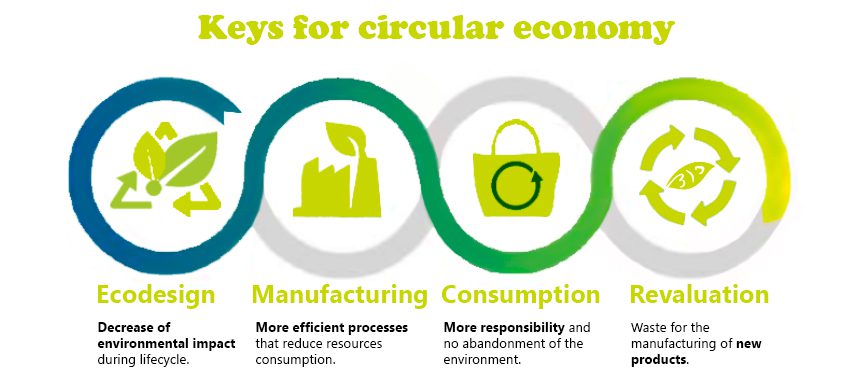

It has not been until some years ago that the consumption industry has become conscious about the need to change the course towards a horizon ruled by the principles of a circular economy: ‘reduce, recycle, reuse’, and towards the use of raw materials that are environmentally friendlier.

What is ecodesign?

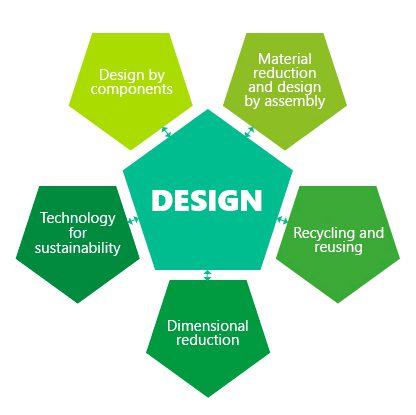

Ecodesign consists in introducing environmental criteria in the phase of design and development of each product (good or service), trying to take preventive actions with the goal of decreasing environmental impacts in the different phases of its lifecycle, from production to its disposal.

How can we apply ecodesign in our package?

It is estimated that it is during the design phase of a package that 80% of its environmental impact is determined.

How can we reduce the carbon footprint from our packaging? In the following section, we will tell you some pieces of advice that will help you during the preparation phase of a package

Avoid plastics, choose plant-based materials. There are different alternatives of renewable energy in the market that can substitute plastic packaging that cannot be recycled.

Packaging made of compostable materials is perfect for foodstuff packages with traces of food inside that are disposed with the organic fraction in the brown waste container. After being treated in an industrial compost facility, they are transformed into natural compost.

Packaging made with one material layer is generally easily recyclable. What is more, they allow lightening the packaging weight leading to a reduction in the costs of our packages.

The use of multilayers can pose difficulties in the recycling process due to the fact that it is necessary to utilize chemical processes that are expensive and aggressive for the environment.

Lightening the weight of our packaging will help us reduce costs in the purchase of our packages, its storage and its transportation, with the subsequent reduction in CO2 emissions to the atmosphere. But it also implies a reduction in the use of raw materials and, finally, in the carbon footprint of our product.

Before purchasing a package, we must make sure that we adjust to the sizes that we need in order to avoid excess material.

Packing products in packages where there is too much excess material can be also harmful for our brand image, for the reason that consumers may think that they are buying a “emptier package than usual”, or simply, they can think that they are being cheated on. Who has not bought a chips bag of metalized material that does not let you see the inside and when opening it felt defrauded?

Avoid these shrinkages and issues by adjusting dimensions to the reel width and packaging length properly.

It is always possible to make processes better in a production process. Take advantage of that room for improvement that is always available and optimize your resources to reduce shrinkages and waste.

Be creative and use the color of the material that you are manufacturing your package with as a support for your design. Avoid printed insides and the use of too many inks.

And remember, less is more!

In order to make a package sustainable it is necessary to use the least amount of material as possible. Reaching a packaging zero waste level is complicated, but it is essential to avoid unnecessary wrapping.

Questions to think about

Before putting these pieces of advice into practice, you should consider a series of questions.

- Are there new materials with better benefits than the usual ones?

- Which of the materials to be used are easily renewable at the end of their useful life?

- What material needs less energy for its production?

- Is a monomaterial possible? What is the smallest number of distinctive materials that could be used?

- In case of using several materials, is their separation in the recycling phase feasible?

- Is the resistance of the used materials adequate for the requirements of its intended use?

- Is it possible to give the product or part of its components a second use at the end of its lifecycle with any changes?

- Are quantities of the material optimized for the least consumption as possible?

- Is there any local supplier from which to buy? Is the company committed to the environment?

- Is the production method of our product efficient in terms of energy consumption and emissions reduction?

- Are renewable energies used in our facilities or during the production process?

- Is it a simple process? Are there duplicities in tasks and tasks that do not add value to the product?

- What messages can we include in the design or labeling of the product to encourage sustainable use habits?

- Is the sustainable characteristic we have given the product easily recognizable?

These are only some examples of the questions that should be answered in your activity development.

Europe 2030 and sustainable development

The plastic sector is key to reach the Sustainable Development Goals (SDG) of the United Nations. These goals are grounded in three main axes: economic, social and environmental.

ECONOMIC

The plastic sector is one of Spain’s industrial engines, and we should keep its strength to be less dependent on other countries’ manufacturing.

SOCIAL

Plastics contribute to preserve the health and safety of people and are ideal for the manufacture of many essential products.

ENVIRONMENTAL

In the food sector, ecodesign and innovation in the plastic packages allow us to consume foodstuffs with the highest security and hygiene. Packaging also contributes to reduce food waste, and thanks to that, food lasts longer preserving that way its properties.

How do we face this challenge?

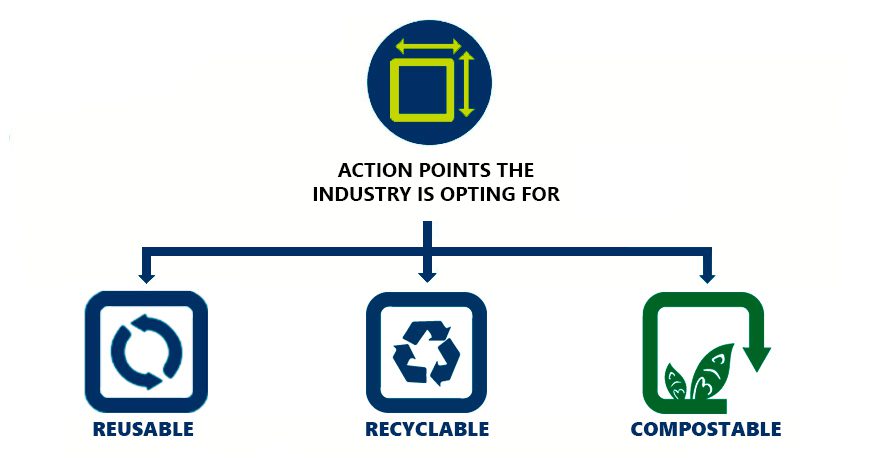

According to what has been established by the European Agenda, by 2030 all packages must be reusable, recyclable or compostable.

The industry of packages manufacturing is generally opting for recyclable Packaging. However, reality is that only a small percentage of flexible packaging ends up being recycled nowadays, with the rest being disposed in landfills, incinerated or in the nature.

There are several projects that are working on the development of chemical methods or on mechanical separation methods that can separate the different layers that make up these structures. However, due to the difficulty in the management, classification and separation of this multilayer waste, in Coverpan we have decided to bet for compostable solutions that transform into natural compost at the end of its useful life.

If you have liked this information, you can visit our website to know all our projects and initiatives, as well as the different sustainable flexible packages that we can offer you at Coverpan S.L.